Precision Craft from Design to Machining

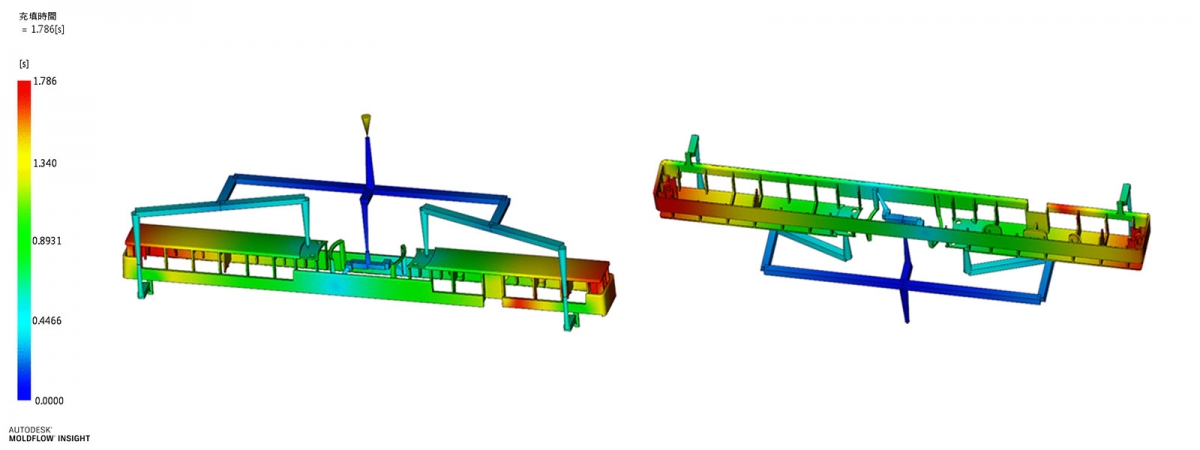

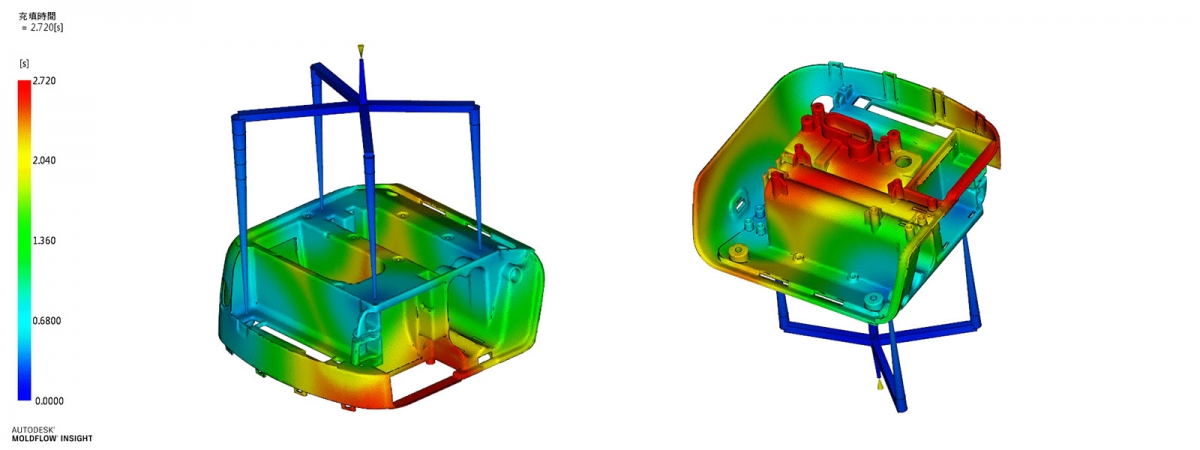

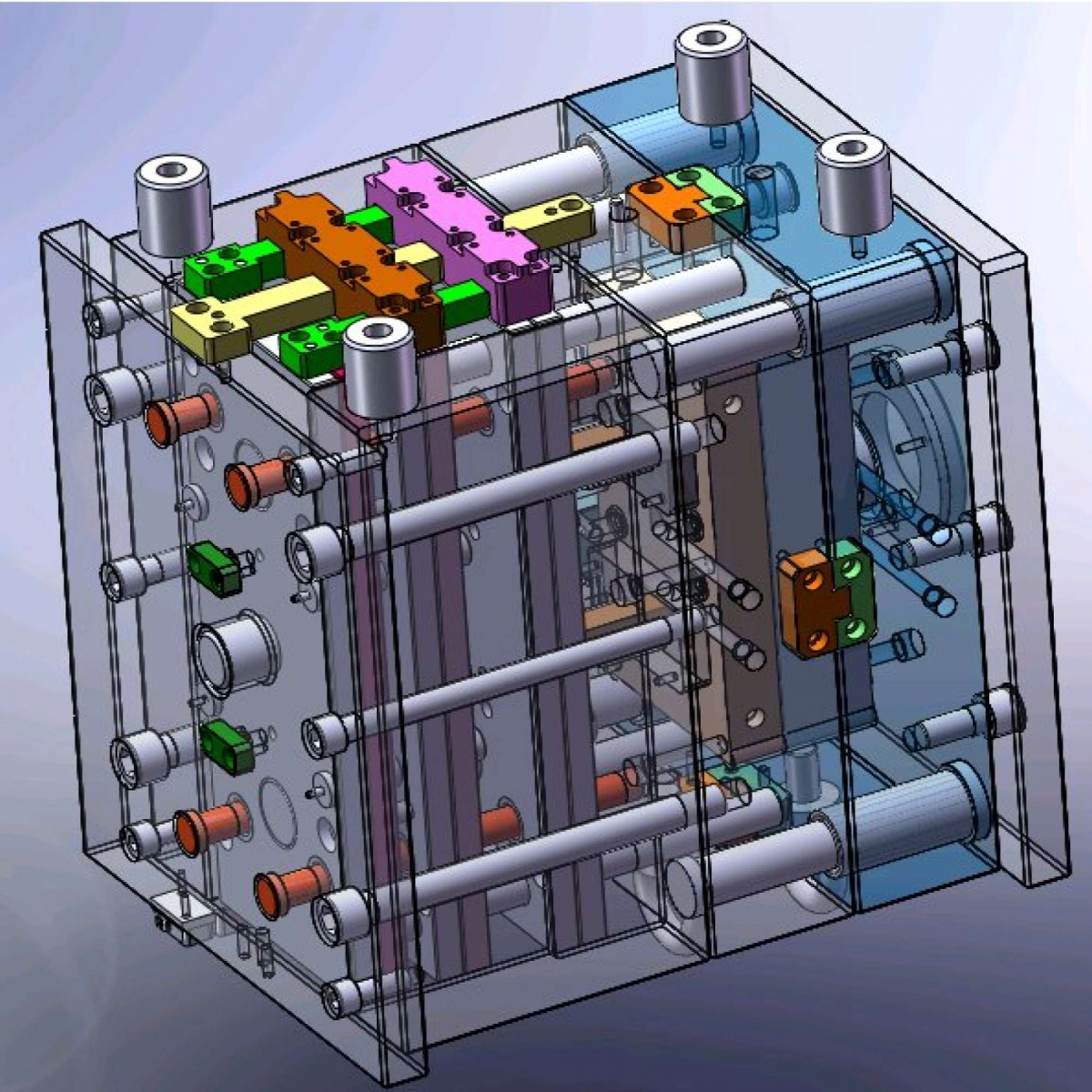

With CAE analysis, we reduce development risk.

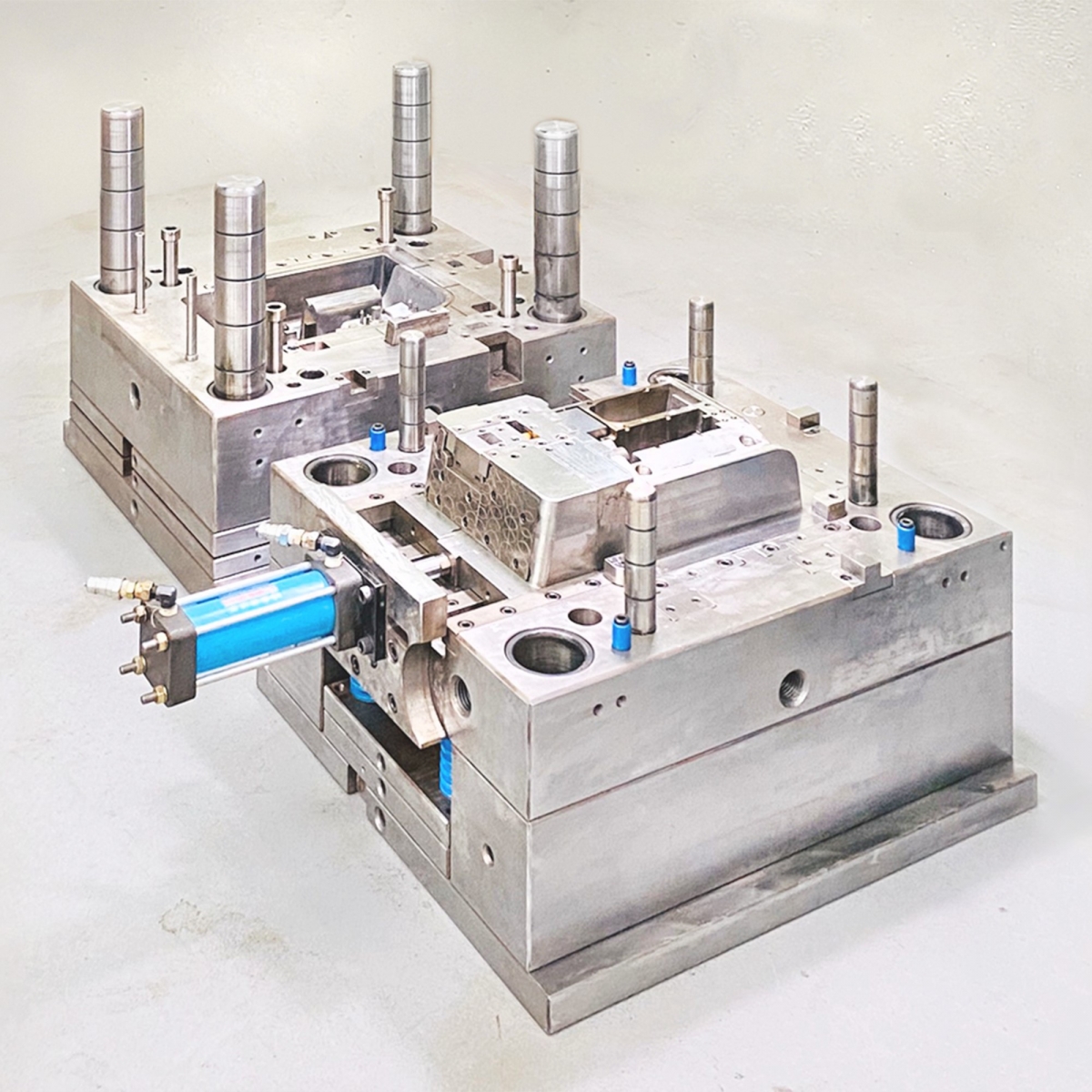

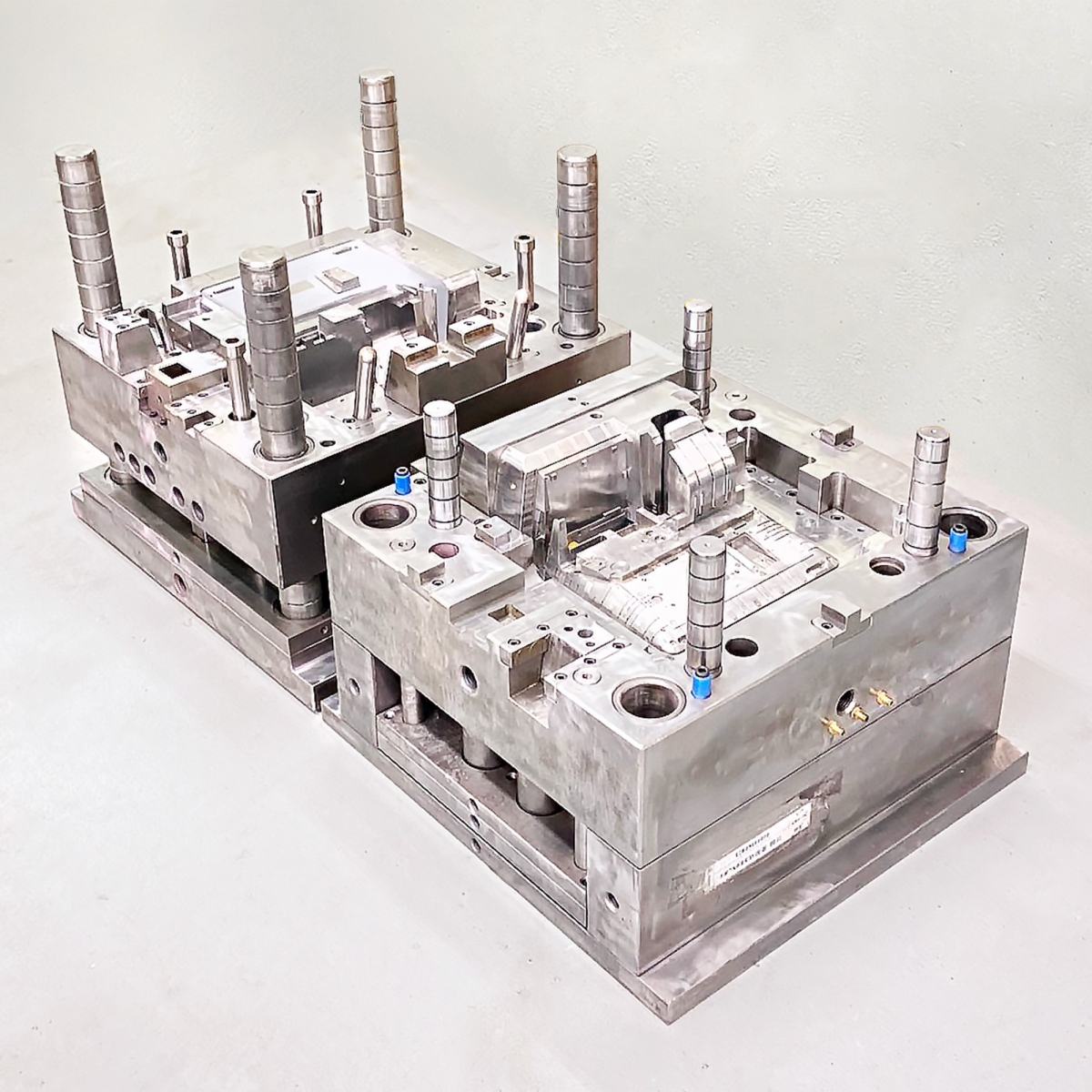

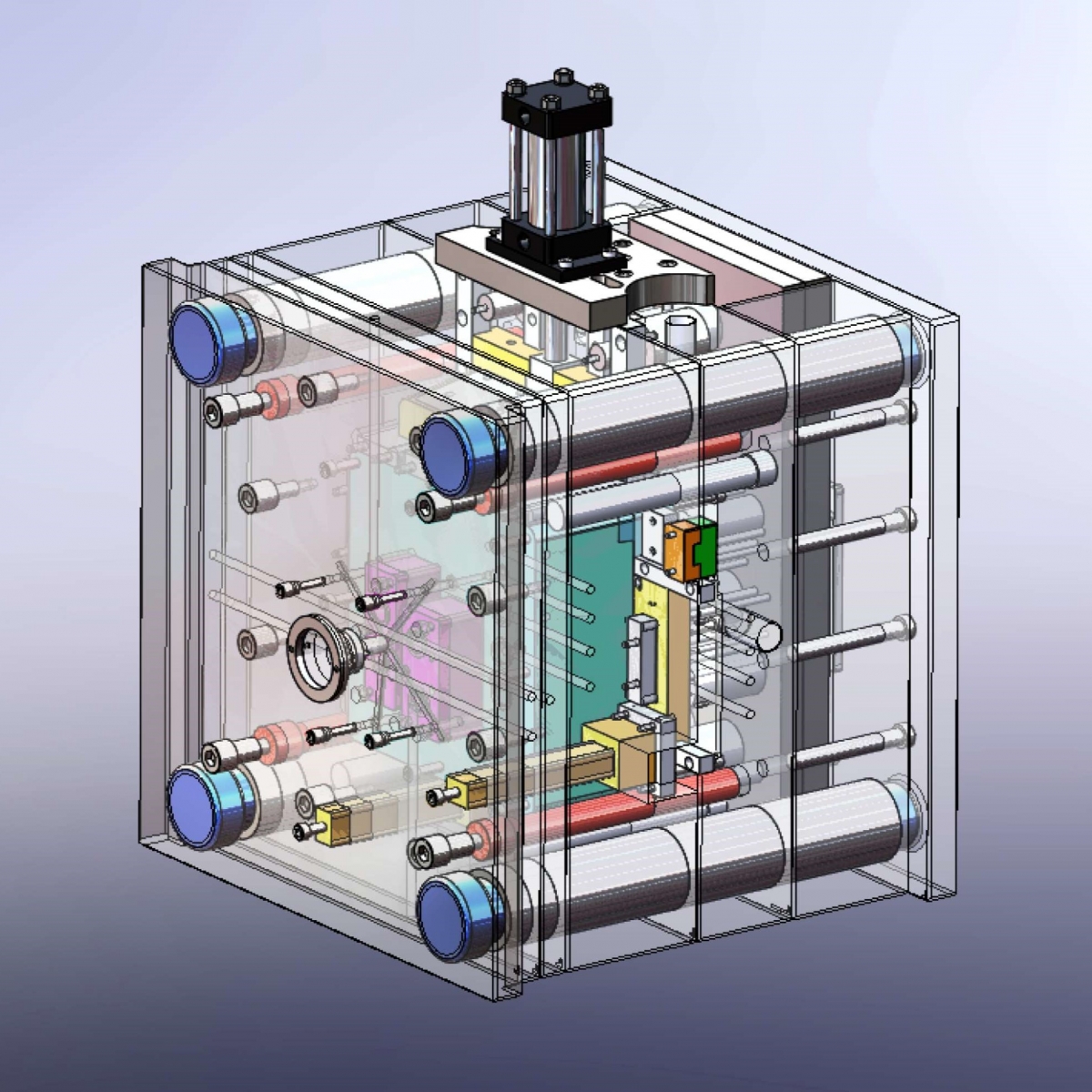

Jawbone has the capability of precision mold built and precision processing equipment. Through mold flow analysis and design review by skilled engineers before making the mold, we find the best solution for product molding. Also, Jawbone strengthens the structure and quality of mold to reduce the need mold modification and to minimize development risk. Provide customers with timely and cost-effective mold development services.

-

Design Assistance

- Product Design Review

Before building molds, Jawbone will provide you with a complete DFM review report and dicuss moldability of your product designs with you step by step.

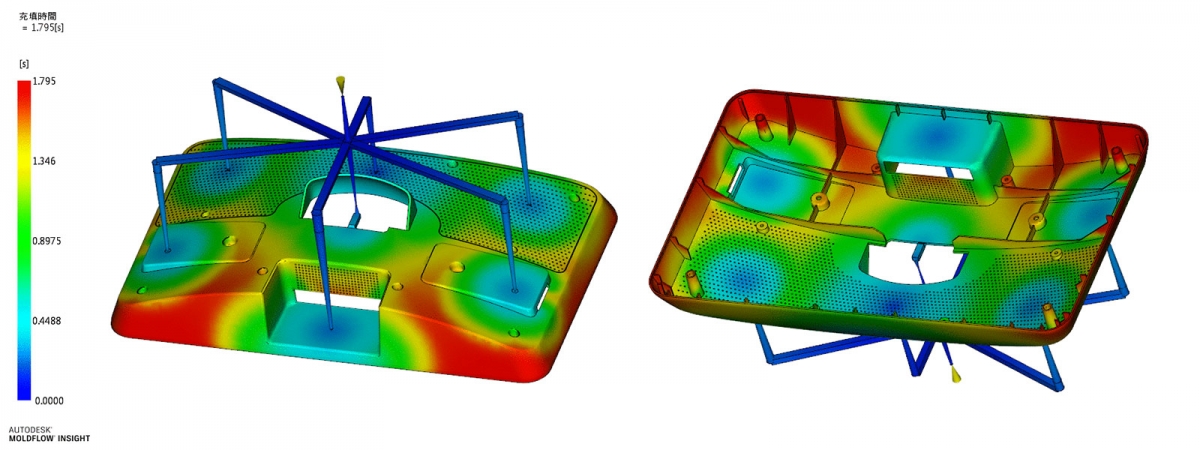

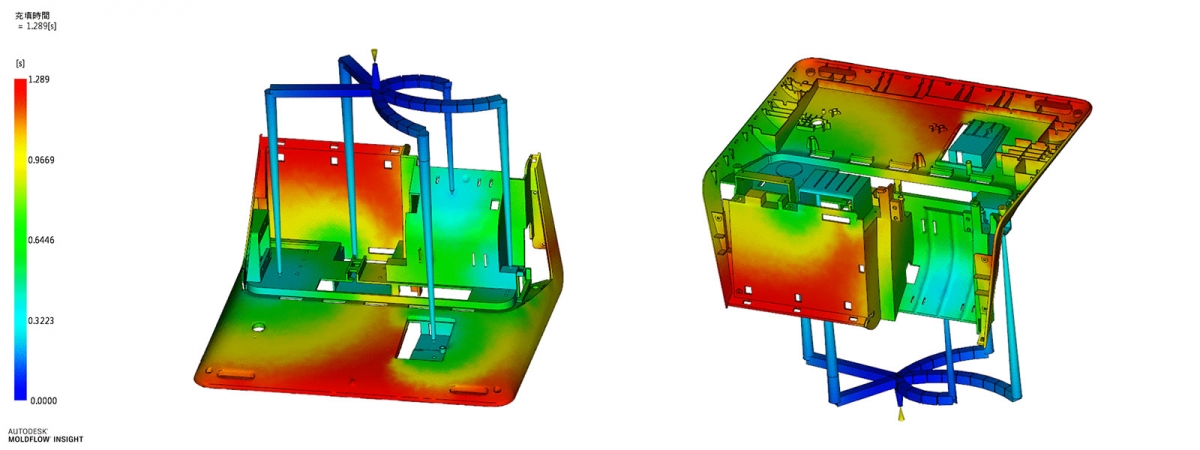

- CAE Mold Flow Analysis

Utilize CAE software for in-depth simulation to get the best solution for part and mold design.

- Product Design Review

-

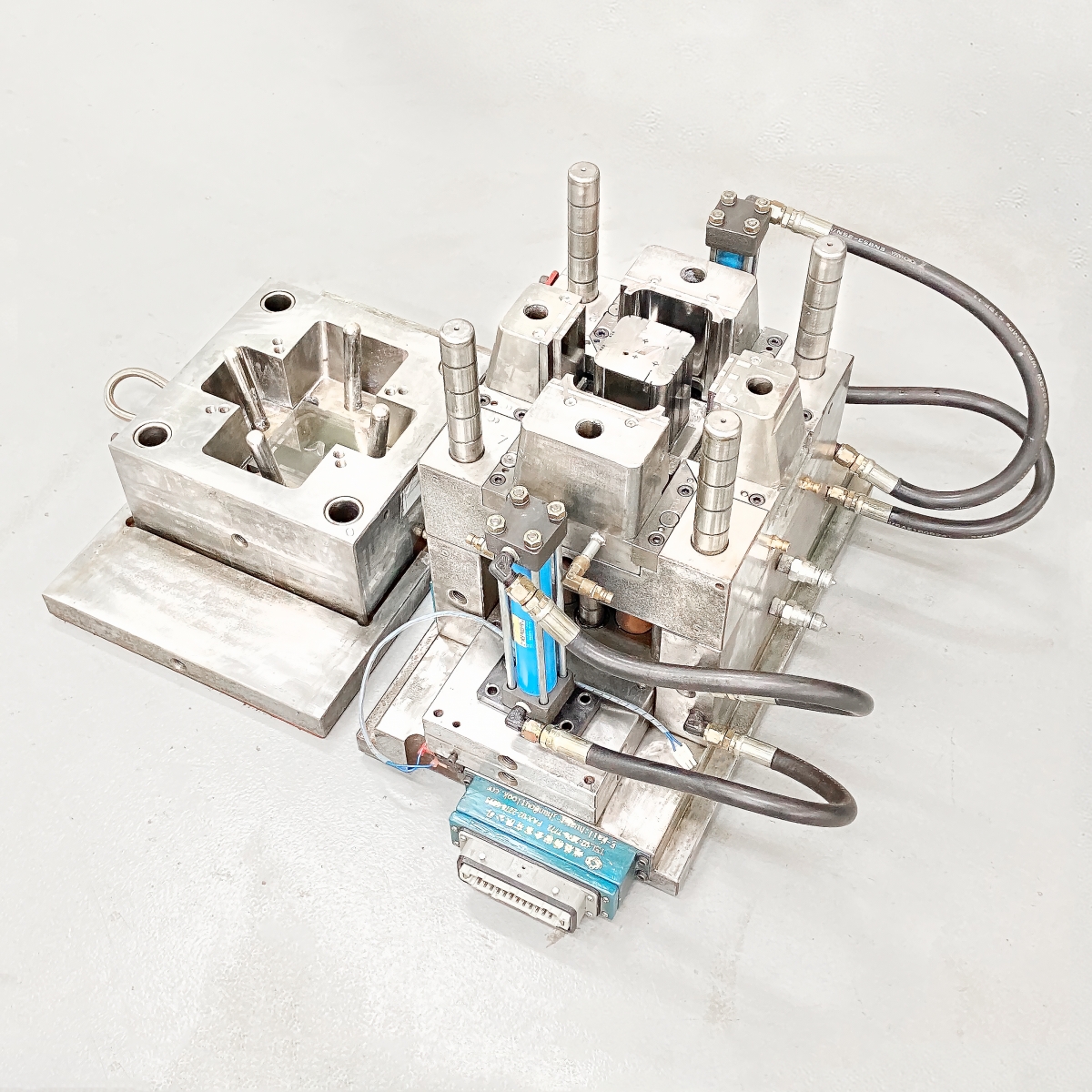

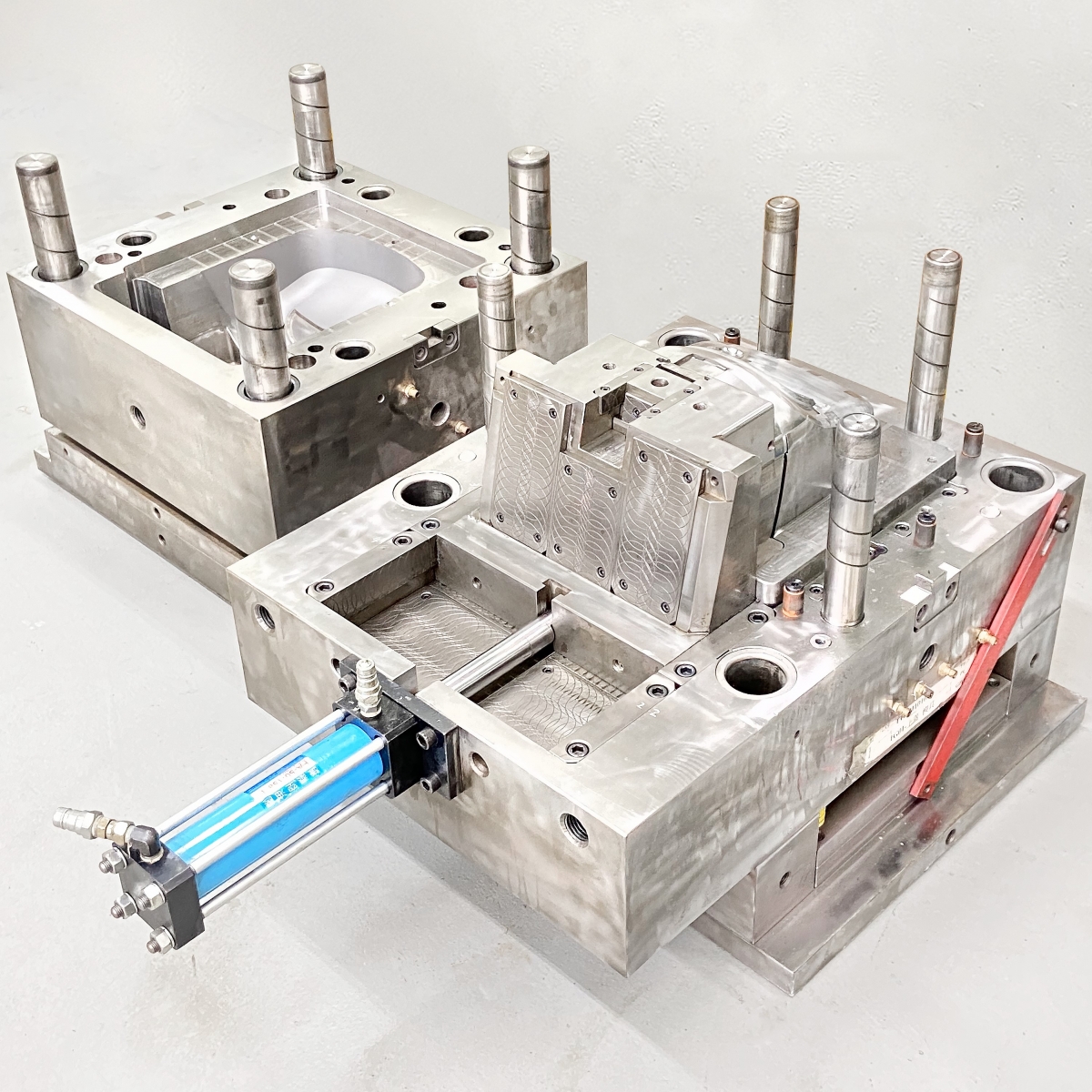

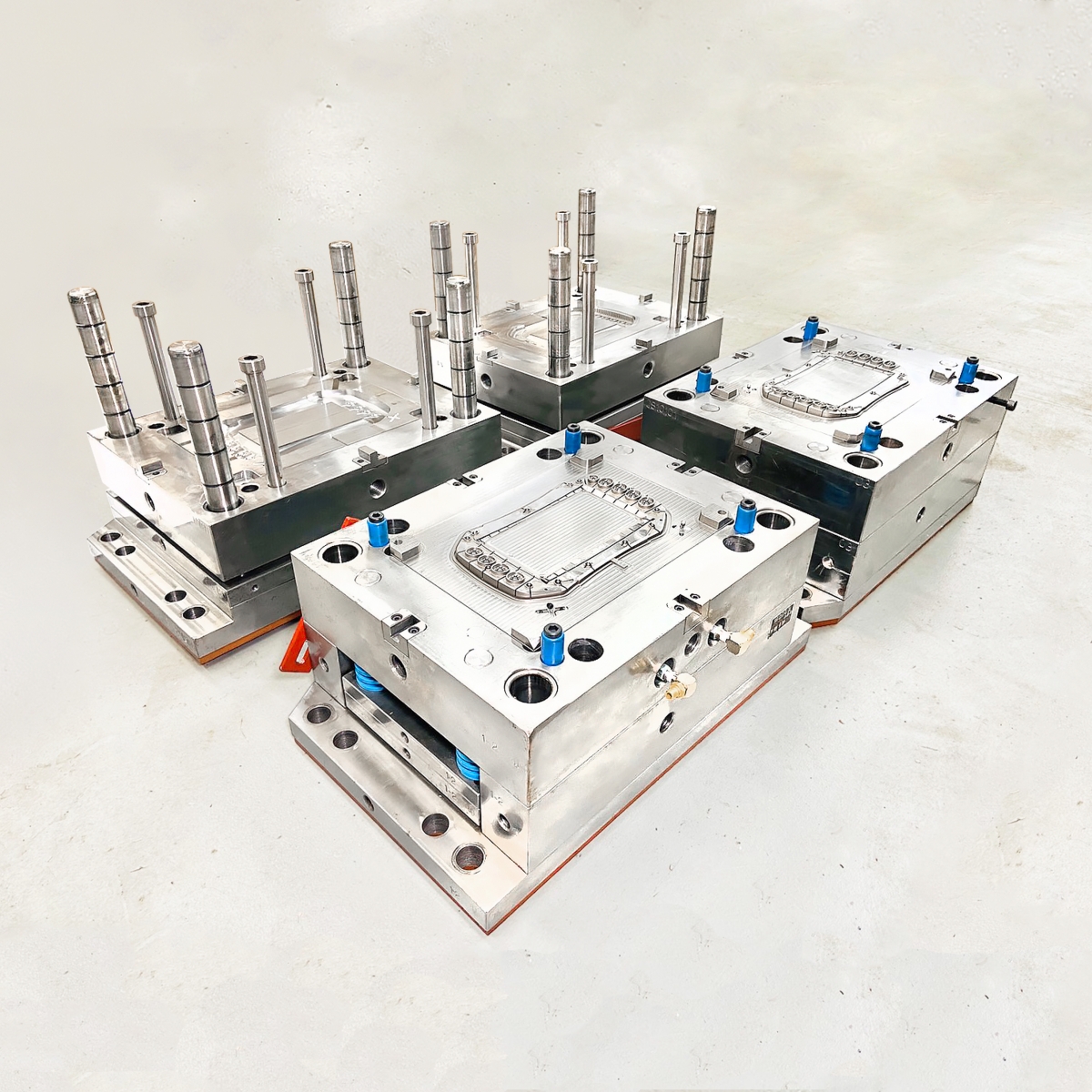

Mold Capacities

Jawbone provides customers with a variety of mold building services, including plastic injection mold, blowing mold, thermoforming mold and metalwork mold.- Standard two-plate mold, three-plate mold, and threaded mold

- Double injection mold

- Insert mold

- Hot runner mold

- Variotherm mold

- Gas assisted injection molding, and blowing molding

- Silicone rubber molding

- Die punch